Aerospace Research Co-op

Solidworks VBA Macros

I worked a co-op position at UVic’s Center for Aerospace Research (CfAR) in Sidney, BC for the summer of 2023. I was tasked with supporting the PhD researchers with their computational models. For example, I wrote a Solidworks macro using VBA that allows the researcher to take a solid or surface airframe model and extract large amounts of airfoil cross section data. The exporter would automatically calculate properties like chord length and area, and it would export hundreds of xyz points and save it to a text file. The file would be formatted such that it could automatically be run in their bespoke simulation program. I ended up writing several of these exporters.

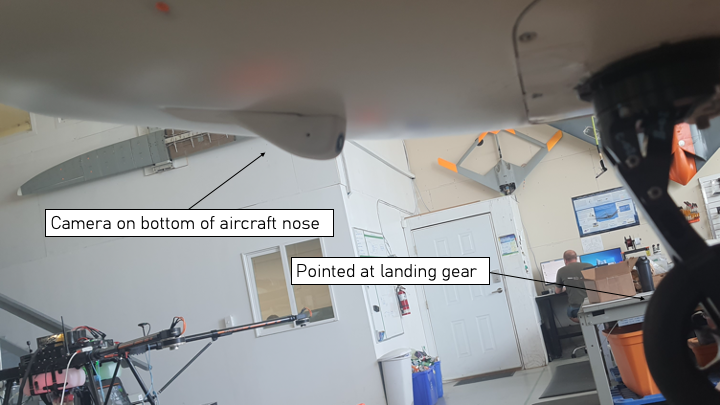

Landing Gear Camera

I designed a camera system to monitor the landing gear on the nose of the EcoJet, which can be seen in the video below. I sourced a drone camera system, designed the 3D printed mount, and integrated them into the fuselage and wiring harness.

Mass Distribution Model

I supported researchers at CfAR by producing a mass distribution model for two different aircraft. Many simple components are accurately modelled in CAD, while others need to be physically measured. For example, the mass and moments of inertia of wiring harnesses or composite fuselages are difficult to accurately estimate in CAD, while a precision-machined aluminum part is more accurate.

The research being done at CfAR required a much more detailed mass/inertia model. The report below documents the work I did to model two different airframes’ mass distributions. Here is a Link to my report, incase the pdf embed is not working on your browser (I didn’t make this website to show off my webdev skills).