Formula SAE Team Principal

Accepting our Cost trophy at FSAE Michigan

Overview

Setting Goals

I was elected to run UVic Formula SAE for the 2023-2024 competition season. The team was motivated to stay competitive in Michigan, so I proposed a list of strong goals aimed at competition lap times, presentation scores, and vehicle reliability. After appointing leads for each vehicle subsystem, we worked together to define quantifiable, measureable subsystem constraints and objectives that support the overall team goals.

Project Planning

I used MS Project to plan the vehicle development, from conceptual design in the summer of 2023 to the first test day on March 2nd 2024. I assigned hundreds of tasks to individuals with estimated completion times and dependencies which allowed critical path(s) to auto-generate. I could also view the workload graphs on each individual and move projects around as needed.

Result

We were able to acheive our long-term deadlines for the vehicle, including the March 2nd first test day that we had marked on the calendar for 7 months. The team had an excellent performance at competition. We won our first ever FSAE trophy in the team’s 20+ year history with our 3rd place finish in the cost report/presentation/drawing event. We also acheived our goal of getting 100 points in the design presentation event. We put down competitive laptimes in all dynamic racing events. On the last day of competition, we had a strong start to the 22km endurance race, but an ECU software failure caused us to retire early.

One of the many gantt charts I generated with MS Project.

This one is for the powertrain development and manufacuturing.

Other Highlights

EV Battery Development

Our EV development was growing, and we were recruiting more electrical engineering students than ever. Unfortunately, UVic does not do high voltage or EV battery research, so there is no established space to develop an EV battery pack. This is the main reason our team’s EV development had struggled to get off the ground since it was started in 2020.

One of the first things I did when elected team principal was establish our team workshop as a safe place to work on and store high voltage battery packs. I helped organize a high voltage safety course at a local college for our electical engineering student members. I worked with our team’s electrical leads to develop safe work documents and emergency procedure documents. We also worked together to source a specialized battery storage box and high voltage PPE. Then, I worked with the mechanical and electrical engineering departments to gain approval to develop EV batteries at UVic for the first time.

Standard Lap

Because the team was motivated to compete with the top teams in Michigan, I established something we call the ‘Standard Lap’. It’s a highly repeatable cone track we set up in the UVic parking lot. Practicing the same track every weekend gives our novice drivers more confidence to push the car closer to its limit. It also allows us to measure our vehicle improvements as we track lap times through the vehicle development process. The photo below shows GPS data overlayed on Google Maps.

Hiring a Co-op Student

I worked with the mechanical engineering lab manager to hire a co-op student for the team. It was a great experience for me. I had the opportunity to go through the hiring process: creating a job posting, reading through résumés, and interviewing multiple canditates. We ended up finding an excellent person to fill the role. I then had the opportunity to supervise the day-to-day work of the co-op student for the entire semester.

Procurement

I spent hours every week purchasing parts and material for both IC and EV vehicle development. I used Monday.com project management system to track all purchases and keep team members updated.

The monday.com purchasing board with 100s of items and 46 different suppliers.

Trip to Michigan

The trip to Michigan International Speedway is more than 4000km. I organized the entire trip, with 6 of us travelling with the trailer and the remaining 15 by air. We packed our race car and everything from our shop into our 27ft enclosed trailer. Finding a rental company with our required towing capacity was nearly impossible, especially when I told them we will put nearly 9000km on their vehicle. I solved this issue by securing a sponsorship deal with a fleet truck company, Driving Force, who supplied us with a brand new diesel F350 for our trip.

Our sponsored towing vehicle and our trailer after arriving in Michigan.

Vehicle Highlights

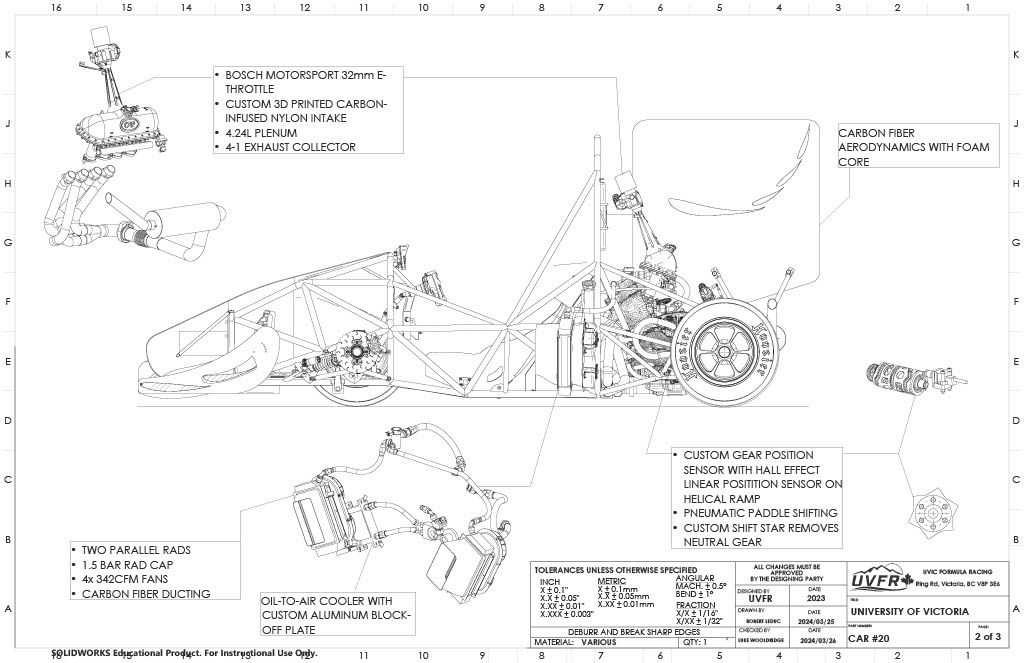

Early in the development process, I asked everyone for ideas and project proposals. With over 100 ideas, we worked together to downselect for the projects that were best suited for reaching our team goals. Some of the larger focuses were

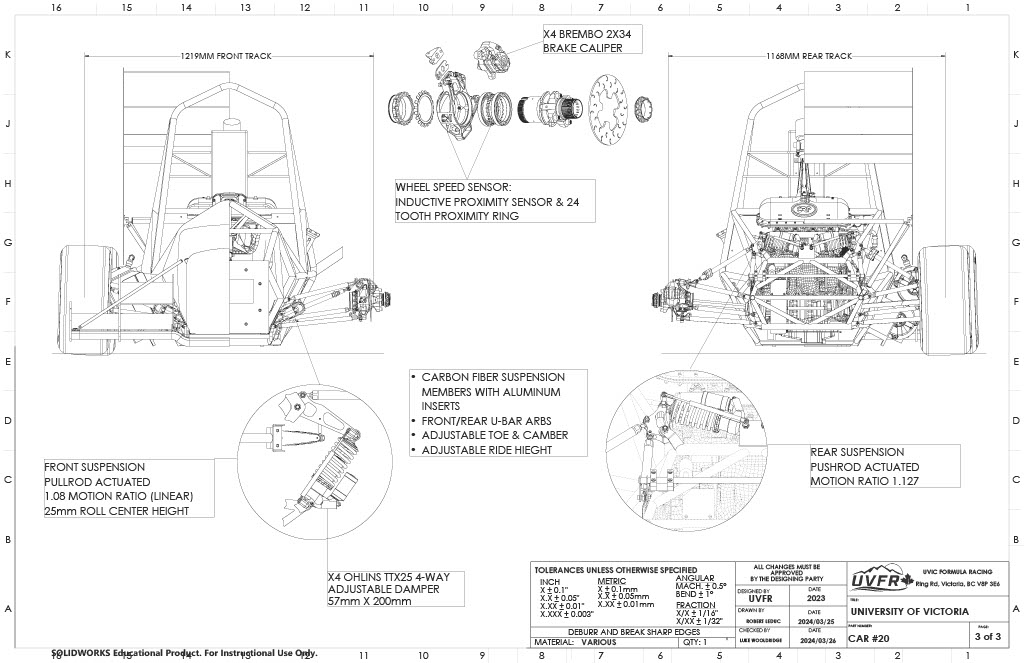

- Front suspension redesign to a low-profile pullrod for better packaging, less drag, improved driver vision, and lowered CG.

- Complete front chassis redesign to accomodate new suspension.

- Steering system redesign to be lighter, more durable, and reduced machining complexity.

- Transmission modifications to remove neutral gear. This removes the risk of getting stuck in neutral.

- Locking carbon fibre clutch handle to accomodate removing neutral.

- Oil cooler to increase cooling capacity.